Whakarāpopototanga: Ka whakamāramahia pototia te mātāpono honohono-whiti, te whakarōpūtanga, te hanganga, te tukanga me ngā taputapu o te rauemi whakamahana polyethylene honohono-whiti silane mō te waea me te taura, ā, ka whakaurua hoki ētahi āhuatanga o te rauemi whakamahana polyethylene honohono-whiti tūturu silane i roto i te tono me te whakamahinga me ngā āhuatanga e pā ana ki te āhua honohono-whiti o te rauemi.

Ngā Kupumatua: Te hononga whakawhiti silane; Te hononga whakawhiti taiao; Polyethylene; Te whakamarumaru; Waea me te taura

Ko te rauemi taura polyethylene whakawhiti-hononga silane e whakamahia whānuitia ana i roto i te umanga waea me te taura hei rauemi ārai mō ngā taura hiko iti-ngaohiko. Ko te rauemi i roto i te hanga waea me te taura whakawhiti-hononga, me te whakawhiti-hononga peroxide me te whakawhiti-whakaata i whakaritea ki ngā taputapu hanga e hiahiatia ana he māmā, he ngāwari ki te whakahaere, he iti te utu whānui me ētahi atu painga, kua noho hei rauemi matua mō te taura whakawhiti-hononga iti-ngaohiko me te ārai.

1. Te kaupapa honohono-whakawhiti rauemi taura whakawhiti-silane

E rua ngā tukanga matua e whai wāhi ana ki te hanga polyethylene whakawhiti-silane: te honohono me te hononga-whakawhiti. I roto i te tukanga honohono, ka ngaro te ngota-H o te polymer i runga i te ngota waro tuatoru i raro i te mahi a te kaiwhakaoho kore utu me te pyrolysis hei rauropi kore utu, ka tauhohe ki te rōpū – CH = CH2 o te vinyl silane hei whakaputa i te polymer kua honoa kei roto he rōpū trioxysilyl ester. I roto i te tukanga honohono-whakawhiti, ka waikurahia tuatahitia te polymer honohono i te aroaro o te wai hei whakaputa silanol, ā, ka whakakotahi te – OH me te rōpū Si-OH e tata ana hei hanga i te here Si-O-Si, ā, ka hono-whakawhiti i ngā macromolecules polymer.

2. Rauemi taura honohono-silane me tōna tikanga hanga taura

E mōhio ana koe, e rua ngā tikanga whakaputa taahiraa-rua me te taahiraa-kotahi mō ngā taura honohono-silane me ō rātou taura. Ko te rerekētanga i waenga i te tikanga taahiraa-rua me te tikanga taahiraa-kotahi kei te wāhi e whakahaerehia ai te tukanga whakapiri silane, te tukanga whakapiri i te kaihanga rauemi taura mō te tikanga taahiraa-rua, te tukanga whakapiri i roto i te wheketere hanga taura mō te tikanga taahiraa-kotahi. Ko te rauemi whakamahana polyethylene honohono-kotahi silane e rua ngā taahiraa me te wahanga mākete nui rawa atu he mea tito mai i ngā mea e kiia nei ko ngā rauemi A me B, ko te rauemi A ko te polyethylene kua whakapirihia ki te silane, ā, ko te rauemi B te puranga matua whakakorikori. Kātahi ka honoa te matua whakamahana ki te wai mahana, ki te mamaoa rānei.

Tērā tētahi atu momo ārai polyethylene hono-whiti silane e rua-taahiraa, e hangaia ai te rauemi A i tētahi ara rerekē, mā te whakauru tika i te vinyl silane ki roto i te polyethylene i te wā e hangaia ana hei whiwhi polyethylene me ngā mekameka peka silane.

E rua ngā momo o te tikanga kotahi-taahiraa, ko te tukanga kotahi-taahiraa tuku iho he momo rauemi mata e ai ki te tauira i roto i te ōwehenga o te pūnaha ine tika motuhake, ki roto i te extruder motuhake i hangaia i roto i te taahiraa kotahi hei whakaoti i te honohono me te extrusion o te matua whakamahana taura, i roto i tēnei tukanga, kāore he granulation, kāore he hiahia mō te whai wāhi atu ki te tipu rauemi taura, mā te wheketere taura anake e whakaoti. Ko tēnei taputapu hanga taura whakawhiti-hononga silane kotahi-taahiraa me te hangarau whakatakotoranga he mea kawemai i tāwāhi, ā, he utu nui.

Ko tētahi atu momo rauemi whakamahana polyethylene whakawhiti-hono kotahi-taahiraa e hangaia ana e ngā kaihanga rauemi taura, he rauemi mata katoa e ai ki te tātai i roto i te ōwehenga o te tikanga motuhake o te whakaranu tahi, te tākai me te hoko, kāore he rauemi A me te rauemi B, ka taea te whakauru tika i te tipu taura ki roto i te extruder ki te whakaoti i te taahiraa i te wa ano ka honoa me te whakaputa i te matua whakamahana taura. Ko te āhuatanga ahurei o tēnei tikanga ko te kore e hiahiatia he extruders motuhake utu nui, nā te mea ka taea te whakaoti i te tukanga whakapiri silane i roto i te extruder PVC noa, ā, ka whakakorehia e te tikanga e rua-taahiraa te hiahia ki te whakaranu i ngā rauemi A me B i mua i te whakaputa.

3. Te hanganga o te hanganga

Ko te hanganga o te rauemi taura polyethylene whakawhiti-hono silane he mea hanga i te nuinga o te wā mai i te rauemi turanga kapia, te kaiwhakaoho, te silane, te antioxidant, te aukati polymerization, te whakakorikori, me ētahi atu.

(1) Ko te kapia turanga he kapia polyethylene iti te matotoru (LDPE) me te taupū rewa (MI) o te 2, engari i ēnei rā tata nei, me te whanaketanga o te hangarau kapia hangai me ngā pēhanga utu, kua whakamahia hoki te polyethylene iti te matotoru raina (LLDPE), kua whakamahia rānei hei kapia turanga mō tēnei rauemi. He maha ngā wā ka pā nui ngā kapia rerekē ki te whakapiri me te hononga whakawhiti nā te rerekētanga o te hanganga macromolecular o roto, nō reira ka whakarerekētia te hanganga mā te whakamahi i ngā kapia turanga rerekē, i te momo kapia kotahi rānei mai i ngā kaihanga rerekē.

(2) Ko te matū whakaoho e whakamahia whānuitia ana ko te diisopropyl peroxide (DCP), ko te mea nui ko te mārama ki te nui o te raruraru, ki te iti rawa hei hanga i te hononga silane kāore e ranea; ki te nui rawa hei hanga i te hononga polyethylene, ka whakaitihia tōna rere, ka taratara te mata o te matua whakamarumaru kua puta, ka uaua ki te pēhi i te pūnaha. Nā te mea he iti rawa, he tairongo hoki te nui o te matū whakaoho i tāpirihia, he mea nui kia horahia kia ōrite, nō reira ka tāpirihia ngātahitia me te silane.

(3) Ko te silane te tikanga e whakamahia ana i roto i te vinyl unsaturated silane, tae atu ki te vinyl trimethoxysilane (A2171) me te vinyl triethoxysilane (A2151), nā te tere o te waikura o te A2171, nō reira he nui ake te hunga e whiriwhiri ana i te A2171. Waihoki, he raruraru kei te tāpirihia te silane, kei te ngana ngā kaihanga rauemi taura o nāianei ki te whakatutuki i tōna rohe iti hei whakaiti i ngā utu, nā te mea he kawemai ngā silane, he nui ake te utu.

(4) Ko te ārai-waikura he mea hei whakarite i te pumau o te tukatuka polyethylene me te ārai-pakeketanga o te taura, ā, he mea nui ake te ārai-waikura i roto i te tukanga honohono silane ki te aukati i te tauhohenga honohono, nō reira, me āta tupato te tāpiri o te ārai-waikura, me whakaaro te nui o te DCP ki te nui i tāpirihia kia ōrite ki te kōwhiringa. I roto i te tukanga honohono-rua-taahiraa, ka taea te tāpiri i te nuinga o te ārai-waikura ki roto i te puranga matua whakakorikori, ka taea te whakaiti i te pānga ki te tukanga honohono. I roto i te tukanga honohono-kotahi-taahiraa, kei roto te ārai-waikura i roto i te tukanga honohono katoa, nō reira he mea nui ake te whiriwhiri i te momo me te nui. Ko ngā ārai-waikura e whakamahia whānuitia ana ko te 1010, 168, 330, me ētahi atu.

(5) Ka tāpirihia he aukati polymerization hei aukati i ētahi o ngā tauhohenga taha o te hononga me te whakawhiti-hononga, i roto i te tukanga hononga, ka tāpirihia he kaihoko ārai-whakawhiti-hononga, ka taea te whakaiti i te putanga mai o te hononga-whakawhiti C2C, ka whakapai ake i te rere o te tukatuka, hei tāpiri, ko te tāpiri o te hononga i raro i ngā āhuatanga ōrite ka mua i te hydrolysis o te silane ki runga i te aukati polymerization ka taea te whakaiti i te hydrolysis o te polyethylene kua honoa, hei whakapai ake i te pumau roa o te rauemi hononga.

(6) He maha ngā wā ko ngā kaiwhakakōkī he mea hanga mai i te organotin (haunga te hononga honohono taiao), ko te mea tino noa ko te dibutyltin dilaurate (DBDTL), e tāpirihia ana i te nuinga o te wā hei puranga matua. I roto i te tukanga e rua-taahiraa, ka takaihia motuhaketia te hononga (rauemi A) me te puranga matua whakakōkī (rauemi B), ā, ka whakaranua ngā rauemi A me B i mua i te tāpiri atu ki te extruder hei ārai i te hononga-mua o te rauemi A. Mō ngā ārai polyethylene hononga-mua kotahi-taahiraa, kāore anō kia honoa te polyethylene i roto i te takai, nō reira kāore he raruraru hononga-mua, nō reira kāore e hiahiatia kia takaihia motuhaketia te whakakōkī.

Hei tāpiritanga, kei te mākete ētahi silane whakakotahi, he ranunga o te silane, te kaiwhakaoho, te antioxidant, ētahi hinu whakahinuhinu me ngā kaihoko anti-parahi, ā, e whakamahia whānuitia ana i roto i ngā tikanga whakawhiti-silane kotahi-taahiraa i roto i ngā tipu taura.

Nō reira, ko te hanganga o te whakamahana polyethylene honohono-whiti silane, ko tōna hanganga kāore i te kiia he tino uaua, ā, kei roto i ngā mōhiohio e tika ana, engari ko ngā hanganga whakaputa e tika ana, me whakarerekē ētahi hei whakaoti, e hiahia ana kia mārama katoa ki te tūranga o ngā wāhanga i roto i te hanganga me te ture o tō rātou pānga ki te mahi me tō rātou awe tahi.

I roto i ngā momo rauemi taura maha, ko te rauemi taura whakawhiti-whiti silane (e rua-taahiraa, kotahi-taahiraa rānei) e kiia ana ko te momo tukanga matū anake e puta ana i roto i te extrusion, ko ētahi atu momo pēnei i te rauemi taura polyvinyl chloride (PVC) me te rauemi taura polyethylene (PE), ko te tukanga granulation extrusion he tukanga whakaranu tinana, ahakoa he hononga-whiti matū me te hononga-whiti irahiko te rauemi taura, ahakoa i roto i te tukanga granulation extrusion, i te pūnaha extrusion Cable rānei, kāore he tukanga matū e puta ana, nō reira, ki te whakataurite, ko te hanga o te rauemi taura whakawhiti-whiti silane me te extrusion whakamahana taura, he mea nui ake te whakahaere tukanga.

4. Te tukanga whakaputa whakamātao polyethylene whakawhiti-hono silane e rua-taahiraa

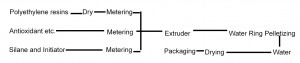

Ka taea te whakaatu poto i te tukanga whakaputa o te rauemi whakamātao polyethylene honohono-rua silane A e te Pikitia 1.

Ahua 1 Te tukanga whakaputa o te rauemi whakamahana polyethylene whakawhiti-tīra e rua-taahiraa A

Ko ētahi o ngā kaupapa matua o te tukanga whakaputa o te whakamahana polyethylene hono-rua-taahiraa silane:

(1) Te Whakamaroke. Nā te mea he iti noa te wai kei roto i te kapia polyethylene, ina tukuna ki waho i ngā pāmahana teitei, ka tere te tauhohe o te wai ki ngā rōpū silil hei whakaputa i te hononga whakawhiti, ka whakaiti i te rere o te rewa, ā, ka puta te hononga whakawhiti-mua. Kei roto hoki i te rauemi kua oti te whakaoti te wai i muri i te whakamatao wai, ka taea hoki te whakaputa i te hononga whakawhiti-mua ki te kore e tangohia, ā, me whakamaroke hoki. Hei whakarite i te kounga o te whakamaroke, ka whakamahia he waeine whakamaroke hohonu.

(2) Ine. Nā te mea he mea nui te tika o te hanganga o ngā rauemi, ka whakamahia te pauna taumaha-ngaro mai i tāwāhi. Ka inehia te kapia polyethylene me te antioxidant ka whāngaihia mā te putanga whāngai o te extruder, ko te silane me te initiator ka werohia mā te papu rauemi wai ki te oko tuarua, tuatoru rānei o te extruder.

(3) Te honohono i te whakaputanga. Ka oti te tukanga honohono o te silane i roto i te extruder. Ko ngā tautuhinga tukanga o te extruder, tae atu ki te pāmahana, te huinga tīwiri, te tere tīwiri me te tere whāngai, me whai i te mātāpono ka taea te whakarewa katoa i te rauemi i te wāhanga tuatahi o te extruder me te whakaranu kia ōrite, ina kore e hiahiatia te pirau wawe o te peroxide, ā, me tino pirau katoa te rauemi ōrite i te wāhanga tuarua o te extruder me te whakaoti i te tukanga honohono. Kei te Ripanga 1 ngā pāmahana wāhanga extruder noa (LDPE).

Ripanga 1 Ngā pāmahana o ngā rohe extruder e rua-taahiraa

| Rohe mahi | Rohe 1 | Rohe 2 | Rohe 3 ① | Rohe 4 | Rohe 5 |

| Te pāmahana P °C | 140 | 145 | 120 | 160 | 170 |

| Rohe mahi | Rohe 6 | Rohe 7 | Rohe 8 | Rohe 9 | Mate waha |

| Te pāmahana °C | 180 | 190 | 195 | 205 | 195 |

①koinei te wāhi e tāpirihia ai te silane.

Ko te tere o te tīwiri whakaputa ka whakatau i te wā noho me te pānga whakaranu o te rauemi i roto i te whakaputa. Ki te poto te wā noho, kāore i oti te pirau o te waikura; ki te roa rawa te wā noho, ka piki ake te matotoru o te rauemi whakaputa. I te nuinga o te wā, me whakahaere te wā noho toharite o te kirikiri i roto i te whakaputa i roto i te haurua-ora pirau o te kaiwhakaoho o te 5-10 ngā wā. Ehara i te mea ko te tere whāngai anake he pānga ki te wā noho o te rauemi, engari ki te whakaranu me te kutikuti o te rauemi, he mea tino nui hoki te whiriwhiri i te tere whāngai tika.

(4) Tākai. Me tākai ngā rauemi ārai hononga-rua silane ki roto i ngā putea hiato konumohe-kirihou i roto i te hau tika hei whakakore i te makuku.

5. Te tukanga whakaputa rauemi whakamātao polyethylene whakawhiti-hono kotahi-taahiraa

Nā te mea kei roto i te wheketere taura te rauemi whakamahana polyethylene honohono-kotahi-taahiraa, he mea hanga mai i te matua whakamahana taura, he nui ake te pāmahana whakamahana taura i te tikanga e rua-taahiraa. Ahakoa kua whakaarohia katoatia te tauira whakamahana polyethylene honohono-kotahi-taahiraa i roto i te tere o te horapa o te kaiwhakaoho me te silane me te kutikuti rauemi, me whakamana te tukanga whakapiri e te pāmahana, koinei te tipu whakaputa whakamahana polyethylene honohono-kotahi-taahiraa i whakanuia tonutia te hiranga o te whiriwhiri tika i te pāmahana whakamahana, ko te pāmahana whakamahana whānui e taunakitia ana kei te whakaatuhia i te Ripanga 2.

Ripanga 2 Te pāmahana o te extruder kotahi-taahiraa o ia rohe ( waeine: ℃ )

| Rohe | Rohe 1 | Rohe 2 | Rohe 3 | Rohe 4 | Flange | Upoko |

| Te pāmahana | 160 | 190 | 200~210 | 220~230 | 230 | 230 |

Koinei tētahi o ngā ngoikoretanga o te tukanga polyethylene honohono-kotahi-taahiraa mā te silane, e kore nei e hiahiatia i te nuinga o te wā ina whakaputa taura i ngā taahiraa e rua.

6. Taputapu whakaputa

He mea nui te taputapu whakaputa hei taurangi mō te whakahaere tukanga. Ko te hanga taura honohono-silane me tino tika te whakahaere tukanga, nō reira he mea tino nui te whiriwhiri i ngā taputapu whakaputa.

Ko te hanga o te rauemi whakamātao polyethylene honohono-rua-taahiraa A, he taputapu hanga rauemi, i tēnei wā he extruder takirua-whakarara isotropic ā-rohe me te pauna taumaha kore-taumaha kawemai, ka taea e ēnei taputapu te whakatutuki i ngā whakaritenga o te tika o te whakahaere tukanga, te whiriwhiri i te roa me te diameter o te extruder takirua-whiti hei whakarite i te wā noho o te rauemi, te whiriwhiri i te pauna taumaha kore-taumaha kawemai hei whakarite i te tika o ngā kai. He pono he maha ngā taipitopito o ngā taputapu me aro nui.

E ai ki te kōrero i mua ake nei, ko ngā taputapu hanga taura whakawhiti-hono kotahi-taahiraa silane i roto i te tipu taura he mea kawemai, he utu nui, kāore he taputapu hanga rite a ngā kaihanga taputapu ā-rohe, ko te take he kore mahi tahi i waenga i ngā kaihanga taputapu me ngā kairangahau tātai me te tukanga.

7. Rauemi whakamahana polyethylene honohono-tūturu a Silane

Ka taea te hono i te rauemi whakamahana polyethylene honohono-tūturu silane i whakawhanakehia i ngā tau tata nei i raro i ngā āhuatanga tūturu i roto i ētahi rā, me te kore e whakamahi i te mamaoa, i te wai mahana rānei. Ki te whakatauritea ki te tikanga hono-tūturu silane tuku iho, ka taea e tēnei rauemi te whakaiti i te tukanga whakaputa mō ngā kaihanga taura, ka whakaiti ake i ngā utu whakaputa me te whakapiki ake i te pai o te whakaputa. Kei te piki haere te mōhiotia me te whakamahi i te whakamahana polyethylene honohono-tūturu silane e ngā kaihanga taura.

I ngā tau tata nei, kua pakari haere te whakamātao polyethylene honohono-tūturu mai i te silane ā-whare, ā, kua nui te rahinga kua whakaputaina, me ētahi painga utu ki te whakataurite ki ngā rauemi kawemai.

7. 1 Ngā whakaaro hanga mō ngā ārai polyethylene honohono-tūturu silane

E rua ngā taahiraa e hangaia ai ngā ārai polyethylene honohono-tūturu silane, me te hanganga kotahi e whai ake nei: te kapia turanga, te kaiwhakaoho, te silane, te ārai matū, te aukati polymerisation me te whakakorikori. Ko te hanganga o ngā ārai polyethylene honohono-tūturu silane e hangai ana ki te whakanui ake i te tere honohono silane o te rauemi A me te whiriwhiri i tētahi whakakorikori whai hua ake i ngā ārai polyethylene honohono-wai mahana silane. Mā te whakamahi i ngā rauemi A he nui ake te tere honohono silane me tētahi whakakorikori whai hua ake ka taea e te ārai polyethylene honohono-tūturu silane te honohono tere ahakoa i ngā pāmahana iti me te kore e ranea te makuku.

Ko ngā rauemi-A mō ngā ārai polyethylene honohono-tūturu o te silane kawemai ka hangaia mā te copolymerization, ka taea te whakahaere i te nui o te silane i te taumata teitei, engari he uaua te hanga rauemi-A me ngā tere honohono teitei mā te honohono silane. Me rerekē te kapia turanga, te kaiwhakaoho me te silane e whakamahia ana i roto i te tunu kai, ā, me whakarerekē kia rite ki te momo me te tāpiri.

He mea nui anō hoki te whiriwhiri i te ātete me te whakarerekētanga o tōna horopeta, nā te mea ko te pikinga ake o te tere honohono o te silane ka arahi pea ki ngā tauhohenga taha whakawhiti CC. Hei whakapai ake i te rere o te tukatuka me te āhua o te mata o te rauemi A mō te whakaputanga taura i muri mai, me whai i te nui e tika ana o te aukati polymerization hei aukati i te whakawhiti CC me te hononga-mua o mua.

Hei tāpiritanga, he mea nui te mahi a ngā whakakorikori ki te whakapiki i te tere honohono, ā, me whiriwhiri hei whakakorikori whai hua kei roto ngā huānga kore-konganuku whakawhiti.

7. 2 Te wā honohono o ngā ārai polyethylene honohono ā-taiao o te silane

Ko te wā e hiahiatia ana hei whakaoti i te hononga whakawhiti o te whakamahana polyethylene honohono-tūturu silane i tōna āhua tūturu, e whakawhirinaki ana ki te pāmahana, te haumākū me te matotoru o te paparanga whakamahana. Ka teitei ake te pāmahana me te haumākū, ka angiangi ake te matotoru o te paparanga whakamahana, ka poto ake te wā honohono e hiahiatia ana, ā, ka roa ake te ritenga kē. I te mea he rerekē te pāmahana me te haumākū i ia rohe, i ia wā, ahakoa i te wāhi kotahi, i te wā kotahi, ka rerekē te pāmahana me te haumākū i tēnei rā me āpōpō. Nō reira, i te wā e whakamahia ana te rauemi, me whakatau e te kaiwhakamahi te wā honohono i runga i te pāmahana me te haumākū o te rohe me te wā, tae atu ki te whakatakotoranga o te taura me te matotoru o te paparanga whakamahana.

Wā tuku: 13 o Ākuhata 2022